The idea for this project came to life a few weeks ago when my wife emailed me at work with a link to a child sized set of table and chairs at Amazon. She wanted to know what I thought about buying this to replace the kid sized folding table and chairs we currently have. The set at Amazon is all birch with a simple, stylish design (pictured left). I like it a lot and it will fit nicely with our decor but I do not like the thought of buying it and I convinced my wife that I could build it. She probably regretted sending the link. Its going to take longer and cost more but she has since warmed up to the idea.

I need to nail this (pun intended, but no nails will be used) because I want to her to turn to me first for furniture and use the web and catalogs as ideas, not shopping carts. I want her to be proud to show her friends what I've done. I know she'll love it regardless, in the same way she loves the pre-school artwork on the fridge and that is one of the numerous reason why she's so great, but I want her to actually love it. I want her to want to buy it if she saw it in a store.

Am I putting too much pressure on myself? Possibly, but that will push me and motivate me to do this right, to really pay attention to detail. Let's get it on.

Design

I started by scouring the web for plans for child sized tables and chairs, but wasn't happy with the results and I got sick of seeing the "16 gagillion woodworking plans for only $19.99" ads. This guy, and probably an army of affiliates, have completely spammed the hell out the "woodworking plans" key word phrase. I tried my hand at affiliate marketing and found it to be a dirty business full of people trying to game google's search results and now I have a strong distaste for websites full of poor content crappy sales pitches.

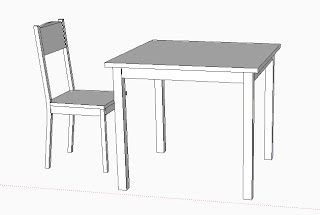

Unsatisfied with the web I tried my hand at Sketchup. I'm a professional computer geek, I should be able to figure this stuff out. Well, thank god for the vast amount of free tutorials on Sketchup's own site as well as youtube. The software isn't exactly intuitive, but the learning curve is short and I found that with a bit of practice I can use it to get the basics of my design on to paper, or uhh, computer screen. It's much cleaner and accurate than trying to draw by hand in terms of seeing how pieces fit and for getting a general sense of what the finished product will look like. You can draw deeply detailed plans but I don't need the images to look like stained wood or to include details like chamfers or rounded corners. For my own reference the basics are good enough.

Taking inspiration from various kid's furniture at Amazon, measuring our existing table and chairs and kids, and discussing it all with my wife, this is what we have come up with. It's simple and strikingly similar to what my wife had originally found but with some modifications. Compared to the amazon version, we raised the table height and made the table top larger. We also raised the seat height as well at the height of the chair back. We're hoping that these changes will allow the table to have continuous use as the kids grow. It may be a smidge big for our youngest right now, but by judging how fast he grows it will fit just fine by the time I finish building it.

We also want the wood to mimic what we already have in the house. Our kitchen table, mere steps from where this table will be, has a maple butcher block top. Our wood floors are made up of various species with beautiful colors and figure. To match these I am going to make the table top, legs, chair seat and back from multiple boards glued together. I'm planning on using birch, like in the one my wife emailed me about, and am hoping to find some with figure and varying color. This should produce a good mashup of the kitchen table and floors. The finish will be left natural with ragged on poly.

Planning

Putting together a cut list for the table and chairs really put the build in to perspective. I've been working off of a drawing a single chair, but when multiplied by four it seems like a much bigger project. I put the list in Excel and used it to calculate board feet to come up with a grand total of just over 16 board feet. I realized afterwards, from reading the notes on the woodworkersresource.com board foot calculator, that using the final dimensioned thickness is a mistake. Since I'll be buying rough stock, I need to calculate using the rough stock thickness, in this case 4/4. That brings the board foot total to more than 18 board feet. That may be less than a $10 difference in cost, but I would have been more then $10 pissed if I ran out of lumber before making all the cuts.

Additionally, if I had planned on using mortise and tenon joinery I would have added in the length of the mortises as well, but as this is my first project, and I don't yet have chisels, I am going to make it a bit easier on myself and use dowels instead. I'll be buying a doweling jig for this, which will make dowel hole placement easy on the chairs since the all the joints will be centered on each joining piece, but that's not the case with the table aprons. I hope the jig has instructions for off set dowel holes. I'm guessing I am going to have to use shims with the jig to get the holes where I want.

Next up is buying the rough wood. I've looked at a couple of places online, one local (about an hour away) and one well known online dealer. I'm leaning toward the local guys since the price of shipping is going to outweigh the convenience of buying online. That and when I emailed both, only the local company got back to me, at 10pm no less. In general my first preference is to buy from locally owned businesses, keep my money in the local economy and such, but all too often the online equivalent is too convenient and often cheaper. Buying wood locally will let me be picky from a large selection too and that weighs heavily as well. How it all turns out will be the subject of my next post on this project.

Thanks for reading!

Jim

Link to the entire "Kid's Table and Chairs series"

Additionally, if I had planned on using mortise and tenon joinery I would have added in the length of the mortises as well, but as this is my first project, and I don't yet have chisels, I am going to make it a bit easier on myself and use dowels instead. I'll be buying a doweling jig for this, which will make dowel hole placement easy on the chairs since the all the joints will be centered on each joining piece, but that's not the case with the table aprons. I hope the jig has instructions for off set dowel holes. I'm guessing I am going to have to use shims with the jig to get the holes where I want.

Next up is buying the rough wood. I've looked at a couple of places online, one local (about an hour away) and one well known online dealer. I'm leaning toward the local guys since the price of shipping is going to outweigh the convenience of buying online. That and when I emailed both, only the local company got back to me, at 10pm no less. In general my first preference is to buy from locally owned businesses, keep my money in the local economy and such, but all too often the online equivalent is too convenient and often cheaper. Buying wood locally will let me be picky from a large selection too and that weighs heavily as well. How it all turns out will be the subject of my next post on this project.

Thanks for reading!

Jim

Jim,

ReplyDeleteThat looks like a good first project. I noticed that you omitted the stretchers from the chairs. While not essential, the stretchers do reinforce the legs. Just something to consider...

Oh, and yes - you will need to use a shim to get non-centred holes from the self-centring dowel jig shown.

Chris

Thanks for chiming in Chris. Hearing from a pro like yourself is a big confidence boost.

DeleteI had considered stretchers but wasn't sure how much of a purpose they would really serve. Though thinking about it a bit more, the boys are rough on... everything.

Thank you for the advice!

Jim